In today's fast-moving design and manufacturing environment, speed, accuracy, and flexibility are obligatory. 3D Prototyping supports these three. From creating early-stage product concepts to the validation of engineering performance or refinement in design details, the ability to produce physical models quickly has become an integrated part of product development workflows. Considering that innovation-driven industries in the UAE have great potential and are growing at a never-imagined pace, 3D prototyping in product development is no longer optional; it is a competitive necessity.

This is achieved by integrating 3D prototyping into the design process: reducing development risks, timelines, and enhancing the quality of the final product. More startups and established enterprises understand how important 3D printing for Prototyping can be when precision and efficiency are a doubt.

What is 3D Prototyping?

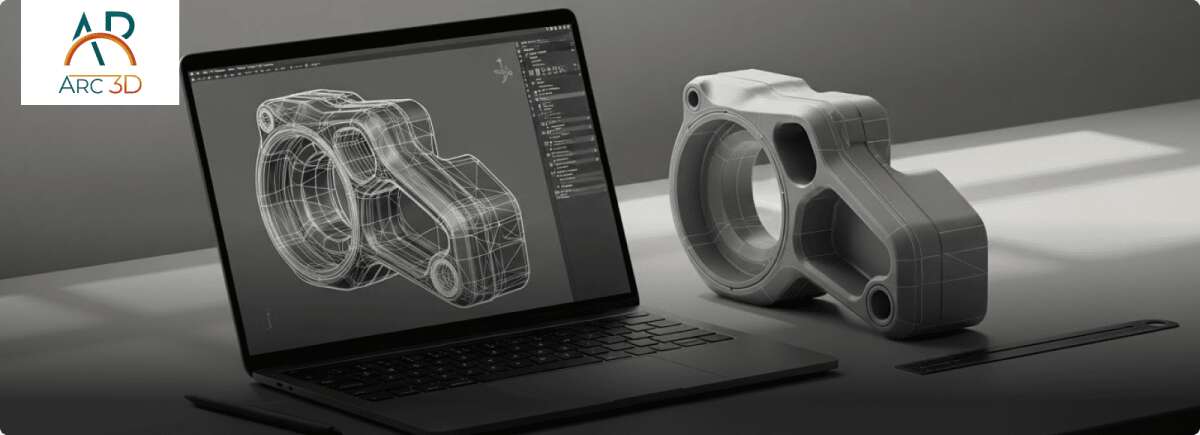

3D Prototyping: A method of creating tangible models directly from digital designs using additive manufacturing technologies. Other than the traditional manufacturing methods, most of which require tooling or molds, 3D prototyping builds an object layer by layer, enabling the making of complex geometries with sophisticated details in a very accurate way.

A three-dimensional prototype represents an idea in physical form. It lets teams measure the proportions, ergonomic qualities, structural soundness, and aesthetic beauty of something in a way not possible with digital renders alone. In many companies, 3D modeling for prototyping often bridges the gap between conceptual thinking and real-world validation.

Demand for professional 3D prototyping services in Dubai and other parts has increased as, in the UAE, industries are looking for faster ways to innovate without compromising on quality. From visual presentation to functional testing and design validation, 3D prototyping provides clarity at every stage of development.

How Does 3D Prototyping Work?

In the process of 3D prototyping, one starts with a digital design. Through special CAD computer-aided design software, designers create a precise 3D model, defining every dimension and feature of the prototype. After finalization, it is then converted into a format suitable for 3D printing.

The selected 3D printing technology then builds the prototype layer by layer using the chosen material. Depending on the project requirements, it may involve high-resolution printing for fine details or robust materials for functional testing. After printing, the prototype may undergo post-processing steps like sanding, curing, or finishing to achieve the desired surface quality.

Knowing rapid prototyping through 3D printing means understanding the smoothness with which design and production have come closer together. Things can be repeated very quickly; hence, improvements can be tried and tweaked without any delay. This seamless workability is the reason 3D Prototyping's trend in UAE-based industries continues to stride further and higher.

How Can You Use 3D Prototyping?

Prototyping 3D helps in the realization of a wide range of applications within design and manufacturing. It is mainly used to validate concepts, conduct tests related to mechanical performances, and present ideas to stakeholders. Appearance prototypes communicate the design intent while functional prototypes test for strength, motion, and assembly.

Many companies use 3D Printing Prototype to detect flaws in their designs earlier and thus save on revisions later. In product development, a prototype bridges the way from an idea to production readiness. For any business offering efficiency, working with a reliable 3d prototype maker gives assurance that prototypes reflect real needs out there.

See Also: From Concept to Creation: Fastest 3D Printing Services in UAE for Modern Businesses

3D Prototyping Technologies Used

A number of additive manufacturing technologies support modern 3D prototyping. Every technology serves different purposes based on resolution, strength, speed, and material compatibility. Common methods include fused filament fabrication, resin-based printing, and industrial-grade systems designed for precision output.

The selection of the best prototyping 3D printer depends on the intended use of the prototype. High-detail visual models may require fine-resolution technologies, while functional testing may require stronger and more durable printing methods. It is here that a professional 3D printing prototype company understands how to align technology selection with project goals.

3D Prototyping Materials

Material selection has immense importance in prototype performance. Plastics, resins, and engineering-grade polymers will be fast-moving in 3D Prototyping because of their versatility and low cost. Each material provides different properties: flexibility, heat resistance, transparency, or strength.

Material choices regarding prototyping are highly dependent on the fact that it can be either a visual evaluation or a functional test. Sometimes, different material iterations were used in order to explore a variety of performance characteristics before finalizing a design.

Read More: Guide to 3D Printing Services in Dubai: Turning Concepts into Precision Prototypes

3D Prototyping: From Concept to Manufacturing

3D prototyping provides a critical stage in development that bridges from concept to manufacturing. It lets manufacturers minimize risks related to tooling errors or inefficient manufacturing methods through the early validation of designs. Prototypes permit teams to simulate real-world usage, test tolerances, and refine assembly processes.

For companies into 3D Prototyping in Product Development, this phase ensures that scaling from prototype to production goes a lot smoother. This stage also addresses small-batch manufacturing, where limited runs of production can be finished without expensive mold investments.

Why opt for 3D Prototyping?

3D prototyping is one step ahead of reaching control in the development process. With 3D, it gives an opportunity to speed up and validate designs, making communications more effective at minimum development costs. A prototype would let stakeholders perceive outcomes more precisely, thereby coming to proper decisions.

In competitive markets like the UAE, a trusted 3D prototyping company allows business operations to be agile and quick to respond. It is often how one can adapt designs quickly that determines whether a product will hit the market successfully.

Advantages of 3D Prototyping in Product Development

Learn More: From Prototype to Production: UAE’s Most Reliable 3D Printing Services

The advantages of 3D prototyping also extend throughout the product lifecycle, from the quicker development time and improved accuracy to supported iterative design. Teams can test several variations for optimal performance without being held up in production.

Another advantage of 3D printing for Prototyping is reduced dependency on traditional manufacturing constraints. This allows for easier innovation, especially where industries require a high level of customization and precision.

3D Prototyping Tools and Software

Successful prototyping depends on advanced CAD software. Such tools grant total control over geometry, dimensions, and tolerances. Simulation features allow designers to see exactly where the stress points and movement would take place before printing.

CAD software for the design of prototypes notices the compatibility of design files with printing technology. Accurately prepared digitally ensures consistency in quality, as well as multiple parts, in a prototype.

Learn More: Guide to Architectural Model Making

Applications of 3D Prototyping across Industries

3D prototyping supports various industries such as product design, engineering, healthcare, architecture, and manufacturing. Each one benefits from the ability to rapidly visualize and test concepts.

In the UAE, 3D prototyping services in Dubai support projects that need an innovation-driven approach with brief timelines and high-quality expectations. From early-stage concept models to functional testing prototypes, they are crucial in modern strategies. Choosing the correct 3D printing technology by taking into consideration the nature of the project, material compatibility, and the accuracy required. Different technologies offer varying strengths, making expert guidance about the most appropriate choice very important. The professional 3D prototype design process confirms that the method selected will be in line with functional and aesthetic ends. Selecting Appropriate Materials for Prototyping Material choice affects durability, finish, and usability. Prototypes for test purposes need stronger materials; architectural model making for presentations may want better surface quality.

Knowledge of material behavior at the test phase ensures realistic evaluation.

Key Considerations in Prototype Design

Clear objectives are the foundation for any successful prototype. It is a must to decide early about scale, tolerance, material properties, and intended use. Addressing these factors reduces rework and improves final outcomes. Best practices for successful 3D prototyping the important things are effective communication, accurate design files, and proper material selection. Iterative testing and refinement are extremely beneficial in making the results reliable. Consistency of prints will ensure dependable evaluation. Overcoming Challenges The common challenges include material limitations, design complexity, and time constraints. These can be overcome through experience, planning, and working with competent professionals in prototyping.

Start Your 3D Prototype Today at Arc 3D

At Arc 3D, supporting projects from conceptualization through refined prototype development, Arc 3D ensures that the deliverables are time-tested and aimed at real-world success. As a key 3D prototyping service supplier in Dubai, Arc 3D ensures a high degree of accuracy, performing quality control procedures right at its integration and with seamless execution. In this way, every prototype supports informed decisions and confident progression toward manufacturing.

Conclusion

Prototyping in 3D brings the modern-age bridge between imagination and execution in design and manufacturing. It converts the 'digital' into real-life models, whereby teams can test ideas, refine functionality, and make confident decisions at this stage, rather than full-scale production. From early-stage visual validation to functional testing and small-batch manufacturing, the role of 3D prototyping continues to expand across industries in the UAE and beyond. At Arc 3D, this process is approached with precision, responsibility, and a clear understanding of real-world applications. Every prototype is developed with accuracy and consistency with the intent to ensure that design integrity is maintained from concept through physical form. With the right blend of expertise, technology, and quality control, 3D prototyping becomes more than a step in development; it's a strategic advantage for companies seeking to innovate with efficiency and move forward with confidence.