Custom 3D Printing Solutions

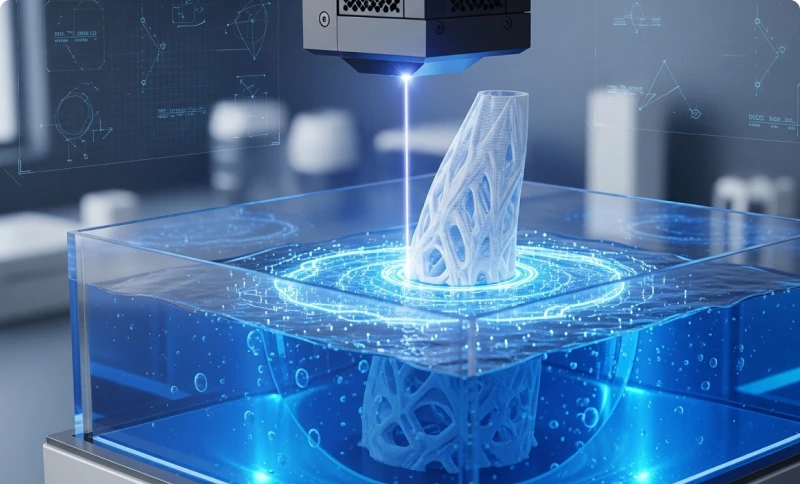

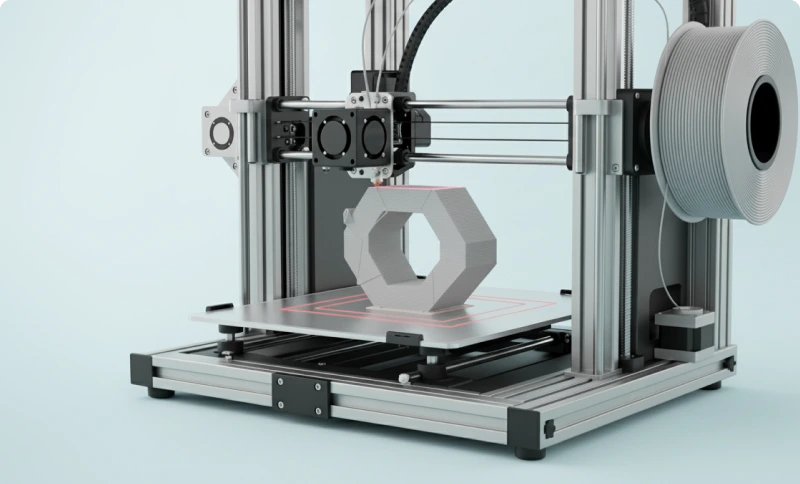

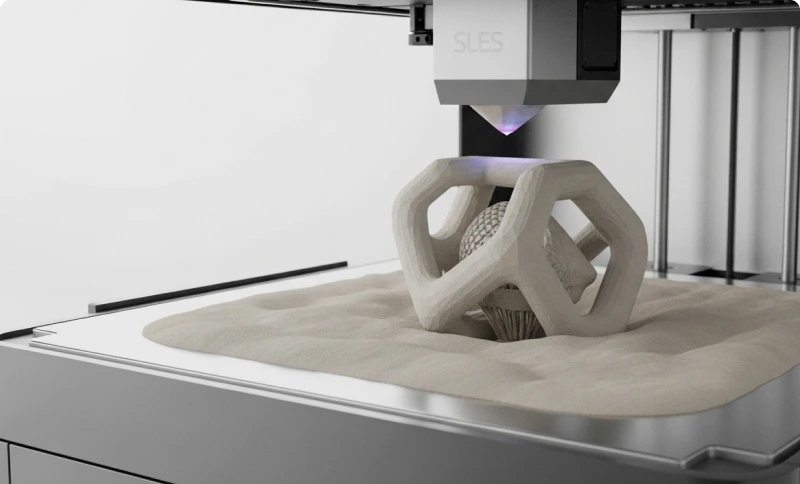

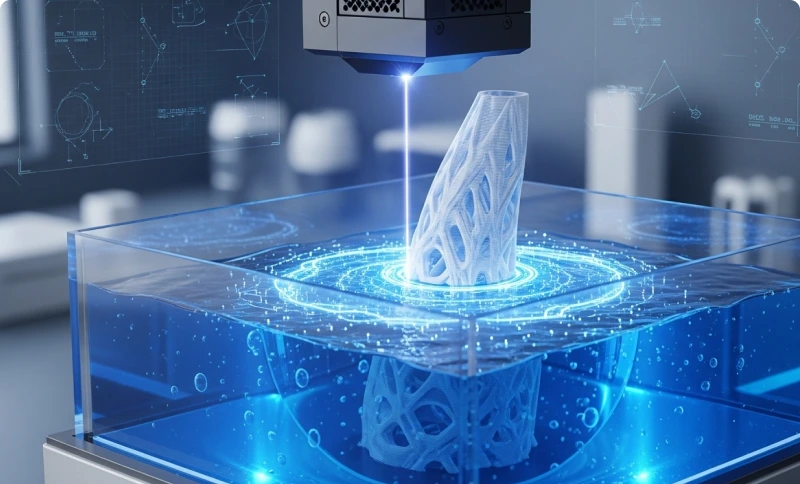

At ARC 3D, all projects go through a systematic process for completion. After getting hold of a 3D model or project, our team checks its appropriateness for the printing phase. The file is then processed by using high-end software to ensure that the output contains the right amount of strength, details, and finish.

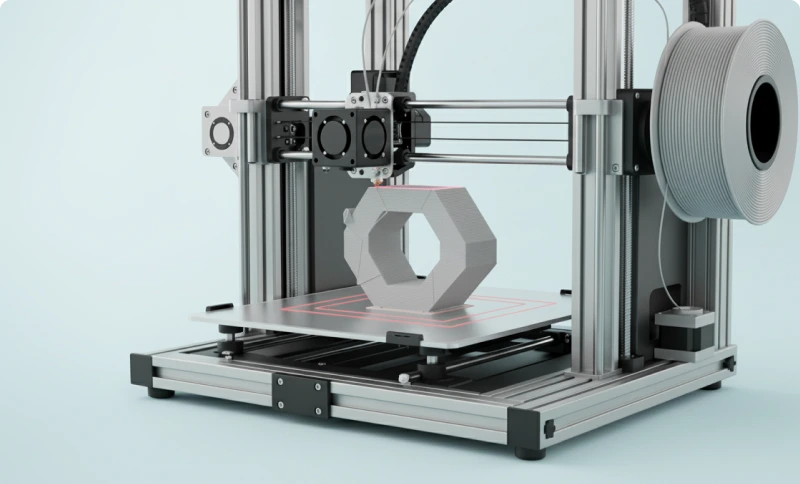

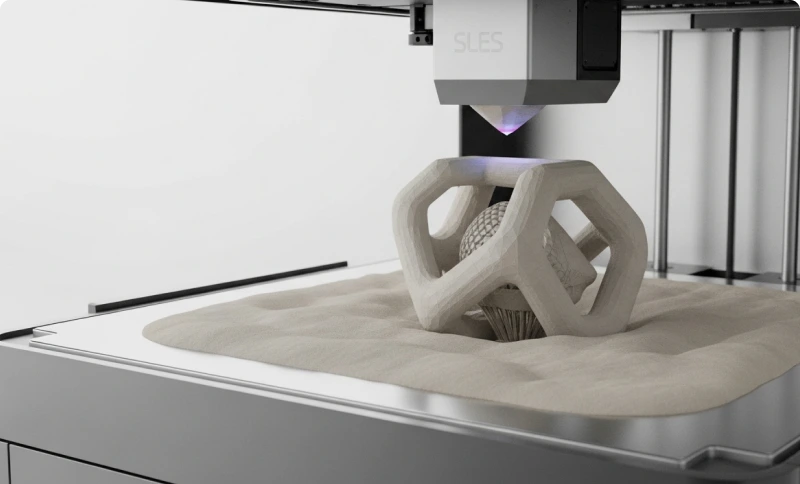

Printing is done through proper use of technology based on the project target. After the production process, the parts are subjected to cleaning, finishing, where applicable, followed by the conduct of thorough quality checks to evaluate accuracy. The produced output is therefore ready for use, presentation, or further processing.