How Prototyping Services Work

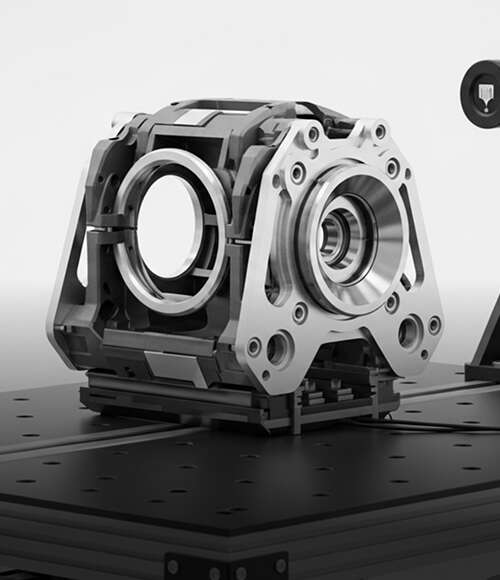

ARC 3D uses a combination of SLA, FDM, SLS 3D printing, CNC machining, and fabrication to deliver prototypes tailored to your needs:

Visual Prototypes:

Highly polished models for presentations, exhibitions, and investor pitches.

Functional Prototypes:

Made with engineering-grade materials, capable of real-world performance testing.

Pre-Production Prototypes:

Simulations of the actual product with exact fit, finish, and usability.

Our team ensures the prototype not only matches the technical design but also has the look and feel of the final product.